What do you do when your aviation facility spans multiple terminals, thousands of assets, and generates critical data across BIM, GIS, and enterprise systems like IBM Maximo… but none of it is connected?

For Jacobs, a global leader in infrastructure consulting, they needed to tackle a major campus improvement project valued at $1 billion. They used FME to integrate disparate data and create a real-time digital twin environment, all without writing code.

Let’s look at Jacobs’ approach and key takeaways for efficiently managing terminals, assets, maintenance schedules, and emergency response.

For a deep dive into this topic, watch the webinar, Building Real-Time Digital Twins with IBM Maximo & ArcGIS Indoors.

Why data integration matters in aviation facilities

Modern aviation facilities rely on a web of digital systems, like BIM models, GIS maps, IoT sensors, and enterprise asset management. But without a cohesive data strategy, critical information is locked in silos, resulting in inefficiency, delays, and lost opportunities for automation.

Implementing real-time data integration is crucial in order to:

- Utilize all of your organization’s data.

- Break down data silos and adopt cross-functionality.

- Create data accessibility and simplify collaboration within your company.

- Keep data synchronized across the organization.

- Enable automation, e.g. automated database updates.

Jacobs’ project exemplifies how unifying these systems can empower field teams with the right information at the right time. Their solution delivered a real-time digital twin by using FME to integrate:

- ArcGIS Indoors for 2D/3D spatial awareness

- IBM Maximo for asset management

- Survey123 for field data collection

- Google Drive & Sheets for documentation workflows

The solution architecture: Making systems talk

Jacobs started with systems already in place: Revit models for building designs, ArcGIS Indoors for visualization, and IBM Maximo for asset data. Integrating them all was the next step. Here’s how they implemented their solution:

- Digital Advisory Board: They established a board to define goals, KPIs, and implementation steps. This was crucial to avoid the common pitfall of tech-first strategies that lack stakeholder alignment.

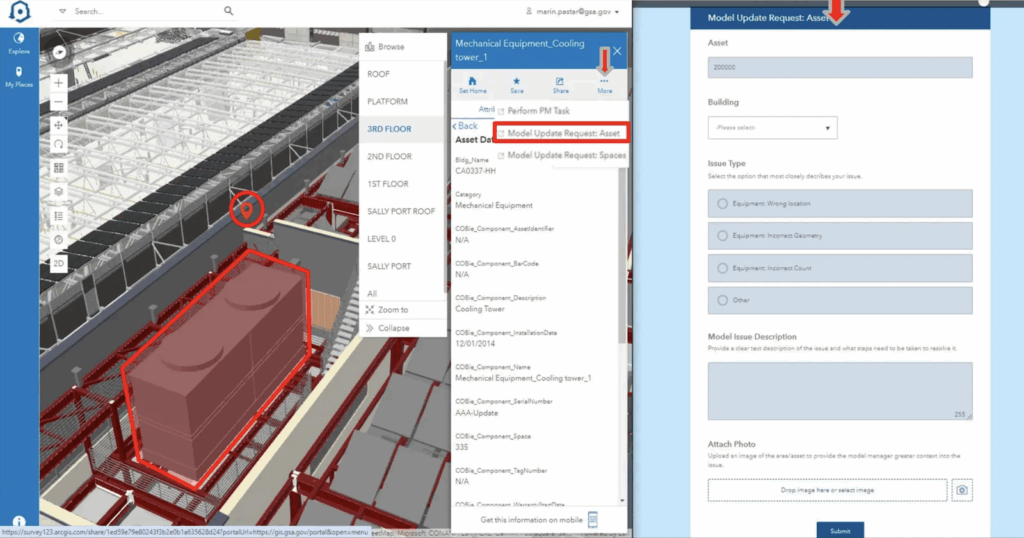

- FME Flow as the Backbone: They used FME to connect the disparate systems in real time. Survey123 forms triggered webhooks that passed data to FME, which routed updates to Maximo or ArcGIS Indoors, while archiving attachments in Google Drive.

- Real-Time Updates: Field inspectors could use tablets to walk up to an asset, capture missing data (like a serial number), and submit a form. Within seconds, asset records were updated across systems.

- Google Sheets as Collaboration Tools: Issues were logged automatically, linking asset IDs, form responses, and attachments. BIM teams could then resolve discrepancies and refine the models, creating a “self-healing” digital twin.

Why FME?

FME’s unrivaled support for 500+ formats and compatibility with thousands of APIs makes it uniquely suited for aviation environments, where data comes from CAD tools, GIS systems, sensors, maintenance logs, and more.

FME also supports:

- LDAP and API-key-based authentication for Maximo

- Webhooks and Survey123 triggers

- Custom queries and update automation

- Visual programming with reusable templates

5 key takeaways for aviation stakeholders

1. Digital Twins are More than Just Models

Too often, a BIM model or CAD file gets handed off and forgotten. Jacobs showed that a digital twin isn’t just a static model, but a whole ecosystem. Integrating Maximo and GIS data allowed their model to reflect the real-world state of infrastructure in real time.

2. Leverage Automation

With FME Flow automating validation, routing, and record updates, Jacobs reduced human error and improved efficiency. For aviation facilities, this means smoother operations, whether you’re managing lighting systems in terminals or HVAC units in hangars.

Plus, automation enables you to embrace real-time data: with every form submission triggering an update, Jacobs created a system that adapts to field inputs instantly.

3. Support Scalability for Long-Term Success

They built FME workspaces that were well-documented and bookmarked, enabling new team members to onboard quickly. Their environment also included development, testing, and production stages, ensuring stability and rollback options. This kind of scalable architecture is critical for large aviation campuses with evolving needs.

4. Understand the Data and Tools

For Jacobs, understanding JSON was important to creating a successful workflow, since this is the language used to pass structured data between Survey123, Maximo, and FME. By creating an architecture that used JSON transformers and webhooks, data seamlessly flowed from Survey123 into systems like ArcGIS Indoors and IBM Maximo.

They also leveraged a range of functionality in FME, like custom transformers to interface with Maximo’s API and meet asset and work order needs, as well as deployment parameters, version control, and more. (Learn how to use FME the FME Academy.)

5. Start with People, not Technology

Digital transformation begins with aligning people, defining goals, and understanding workflows. The technology should serve those needs, not drive them.

Whether your digital twin journey is just beginning or you’re already piloting integrations, this case study shows what’s possible when you empower your teams with real, connected data.

Learn More

Join our FME Special Interest Group: Airports & Aviation